In modern manufacturing industry, automatic production equipment has become an indispensable part. The production workshop of Dezhou Sanhe Electric Co., Ltd. is equipped with a number of advanced automatic production equipment. These equipment realize automatic production, fully automatic winding and fully automatic assembly, which greatly improves the production efficiency while ensuring product quality. Next, we will introduce the specific features of these advanced devices.

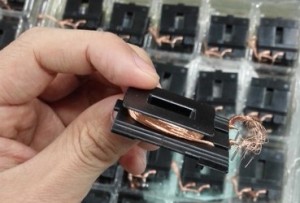

First of all, the large 12-axis automatic winding machine can ensure good alignment through fast winding operation and high precision winding technology. The device's sensors can quickly detect the current inside the coils and quickly adjust the machine's speed, dramatically increasing production efficiency without compromising the quality of the winding.

Secondly, automatic dispensing equipment greatly saves manpower, good consistency of glue quantity, and high processing efficiency. Dispensing is a very important process in electronic and electrical manufacturing, and the traditional manual dispensing mode frequently occurs manual error, resulting in a lot of waste. Once the automatic dispensing equipment is used, it can not only ensure the consistency of dispensing amount, but also avoid these human errors and significantly improve production efficiency.

In addition, compared with manual peeling, automatic laser peeling equipment has higher processing efficiency and consistency. Using laser technology to replace the traditional manual or mechanical peeling, can be faster to complete the process, while ensuring no damage to the product. Due to the use of advanced automatic control system, high production efficiency, and product consistency has been greatly improved.

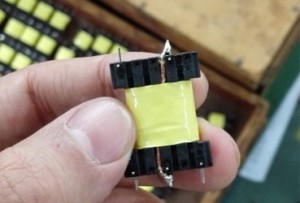

Finally, automatic soldering equipment to achieve solder depth, time, action of automatic control, effectively ensure solder quality, and improve processing efficiency. Soldering is an indispensable process in electrical manufacturing, but the traditional manual welding is easy to be disturbed by human factors, which leads to soldering errors and aesthetic problems. In contrast, automatic control of solder equipment can accurately control each parameter, so that the quality of solder has been greatly improved.

Dezhou Sanhe Electric Co., Ltd. to ensure quality, improve efficiency, reduce cost as the goal, the manufacturing center for continuous reform and optimization, and in the advanced technology, automation equipment import constantly efforts. By investing in advanced automation equipment, the company can significantly improve production efficiency and achieve a highly automated production process, thus providing customers with more reliable products and better service.

Post time: Mar-20-2023