Encapsulated EI41 Silicon Steel Core Power Potting Low Frequency Transformer

Introduction

In the circuit, the reactor plays a role of controlling harmonic current, improving output high-frequency impedance, efficiently suppressing dv/dt and reducing high-frequency leakage current . It helps protect the inverter and reduce noise of the equipment.

Parameters

| NO. | ITEM | TEST PIN | SPECIFICATION | TEST CONDITION |

| 1 | Inductance | 1-12 | 3.5-5.5mH | 1kHz,0.3V |

| 2 | DCR | 1-12 | 350mΩ MAX | AT 20℃ |

| 2.Operation Temp Range: | ||||

| -25℃ to 70℃ | ||||

| The maximum temperature rise:40℃ | ||||

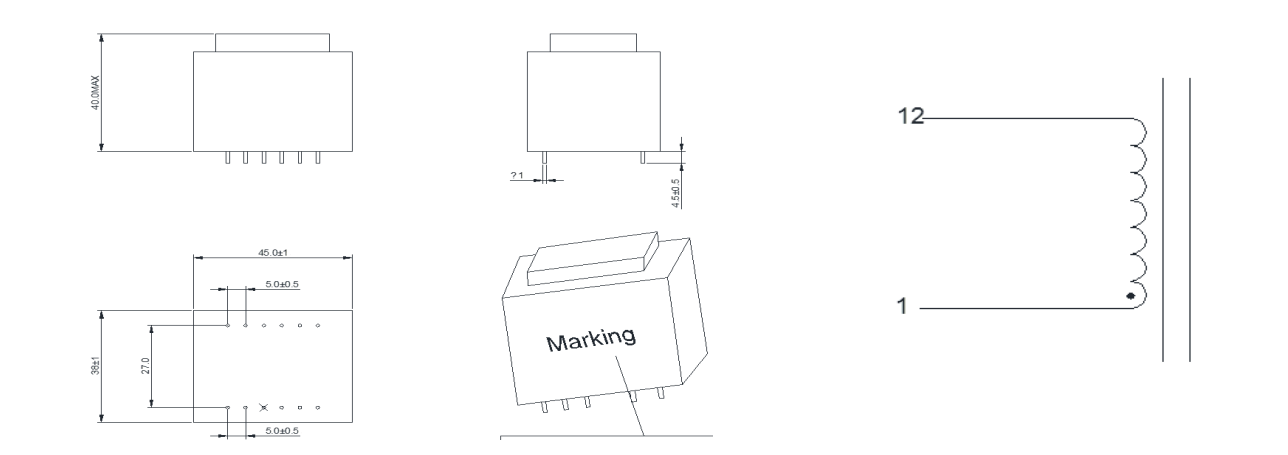

Dimensions:(Unit: mm)& Diagram

Features

1. The magnetic core is welded to a whole by argon arc welding process

2. Ferrite core of silicon steel has its own air gap

3. Epoxy resin potting process

4. Laser coding

Advantages

1. The iron core welding process ensures good saturation characteristics and reduces noise caused by the iron core resonance

2. Potting with epoxy resin, iron core additionally wrapped with cured resin reduces noise generated by resonance.

3. Low no-load current, low loss

4. Good impedance

Video

Certificates

Our Customers